When we talk about modern world many things came into our

mind like huge Building constructions, Bridges, Infrastructure etc. In order to

provide long life and to prevent those from natural disastrous industrial galvanized steel beams are being used globally. Galvanizing provides steel long life as well as

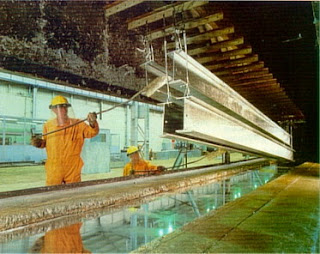

prevents it from getting rusty. Galvanizing is basically a process in which

steel or metal is being dipped in hot pond of zinc oxide to form a very strong

and protective layer that provides steel long life.

We have been supplying

hot dipped galvanized steel products throughout the world for more than five

years. Our Galvanizing Plant has two Galvanizing lines and can fabricate steel

with zinc coating from 400g/sqm to 1200g/sqm.

Our Hot Dipped Galvanizing Plant

is certified with following Quality Assurance:

- ISO: 9001 Quality Management System

Certification

- ISO: 14001 Environmental Management

System Certification and

- GB/T--28000 Occupational Health and

Safety Management System Certification

We are committed to provide quality products to our

customers, which is the main reason behind the acceptance of our products

globally.