Construction companies

used industrial galvanized steel beams to build houses, buildings and

infrastructures in large scale. It is coated with the layer of zinc oxide and

helpful to avoid corrosion. Zinc oxide is very useful which protects metals

from rust, give durability and hard to scratch. Galvanized Steel is

important for fabrication and in industrial applications such as construction,

transportation, agriculture and electric power.

There are numbers of

ways to protect steel from corrosion but the most common way is to combine

steel with zinc oxide. The mixture of both will increase the life of steel and

helpful for the contractors as well in long term. Zinc is involved in the form

of paint because it does not coat with the other metal.

Benefits of Hot Dip Galvanized Steel

|

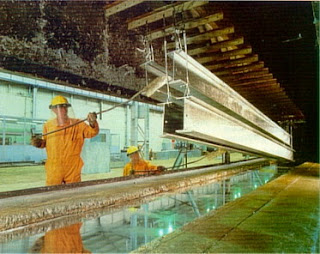

| Hot Dip Galvanizing Process |

It is highly resistant to rust, which is a major

component of steel that after reacting with moisture and oxygen will eventually

collapse. Zinc layers are performing their role as a barrier to prevent those

elements from reaching the steel very quickly. It also develops an important

layer known as patina that offers further protection, which is the mixture of

salts, zinc oxides and other compounds.

· Sacrificial layer is the outer one layer which

is performing its role as a protective steel wall that protects the steel very

well.Hot Dip Galvanizing process plays a very important role and contractors

are willing to use it to give a long life of their infrastructures.

0 comments:

Post a Comment